Applications

of Screwdriver

Screwdrivers

are one of the most necessary and sought-after tools for any tool kit. For

loosening and tightening different kinds of fasteners, there is no option for

screwdrivers. These are used in various applications like

·

Opened the mobile

phones

·

Opened the

Electronics and electrical equipment

·

Opened the

computers

·

Carpentry and

woodworking

·

Mechanical and

industrial production

·

Metal worked and

fastening wood to metal

·

Flammable environments,

etc.

Screwdrivers

Sizes:

The

screwdrivers are available in many different sizes. These are usually sized as

standard large, medium, and small. Certain screwdrivers are also sized to use

in tightening or confined spaces. The screwdriver tip width and the length of

both the blade and the overall tools are generally measured in millimeters.

Again,

depending on the worker, the screwdriver sizing can vary. For example, Phillips

screwdriver provides four standard screwdriver sizes ranging from no 0 to 4,

where #0 describes the smallest screwdriver. On the other hand, certain

screwdrivers are sized based on the Torx size. The size is specified by the

letter T replaced by a number. For instance, T10 screwdrivers. This screwdriver

sizing approach ranges from tiny screwdrivers to T45 and beyond. The same

sizing system is applicable to screws as well which in turn helps in choosing

the screwdriver size for a particular sized screw.

Types

of Screwdrivers;

In

general, screwdriver types are resolute based on the drive tip shape to fit

specific kinds of screws. Again, certain kinds of screwdrivers are specific

tools for particular industries. Using the right kind of screwdriver to the

screw saves effort and, time, the following section gives a guide to the most common

types of screwdrivers.

Crosshead

Screwdrivers or Phillips; Screwdrivers

·

Torx or Star

Screwdriver

·

Insulated

Screwdrivers;

·

Torque

Screwdrivers

·

Flathead

Screwdrivers

·

Tri-Wing

Screwdrivers

·

Pozidriv

Screwdriver

·

Hex Screwdriver

·

•Square Screwdriver

·

Electric

Screwdrivers and Impact Drivers

·

Precision

Screwdrivers

·

Magnetic

Screwdrivers

· Ratchet Screwdrivers

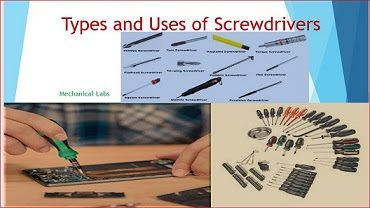

Fig.

1: Different Types of Screwdrivers

1.

Crosshead Screwdrivers or Phillips; Screwdrivers;

Crosshead

screwdrivers or Phillips screwdrivers are considered to fit screws with

Phillips heads having a crossed shape recess. These are available in sizes from

size zero to size four. Phillips screwdrivers are imaginary to cope with higher

torsion. Their angled tips allow appropriate deeper into the screw head which

decreases the chances of the driver sliding out.

2.

Torx or Star Screwdriver;

Torx

screwdrivers are most popular by various names like star head screwdrivers,

pointed screwdrivers, or six-point screwdrivers. The trademark name for a

six-point star-shaped intrusion in the screw head is Torx. This kind of

screwdriver is suitable for assigning higher torques without the tool slipping.

Torx screwdrivers are obtainable in a range of sizes. These use a numbering

system that starts with the letter T followed by a number, for example; T8,

T14, T10, T26, etc. With the increase in the numbers, the size of the tooltip

increased. Torx screwdriver is widely used in Automotive, factories, and

industries.

3.

Insulated Screwdrivers;

Insulated

screwdrivers provided added safety in potentially hazardous situations and

because of this, they are also known as safety screwdrivers. These types of

screwdrivers are widely popular among electricians. The insulation is usually

made from non

4.

Torque Screwdrivers;

The

torque screwdrivers are quite similar to a torque wrench and are used to

provide a specified controlled torque. These work using a torque-limiting

clutch that has a limit on the applied force beyond a certain threshold.

5.

Flathead Screwdrivers;

Flathead

Screwdrivers are also known as slot-headed screwdrivers. These types of

screwdrivers are quite common and have multi-purpose applications. With their

flattened tip, flathead screws provide a linear straight movement.

6.

Tri-Wing Screwdrivers;

Mostly

used for specialized implements like consoles, cameras, and mobile phones,

Tri-wing Screwdrivers possess quite small tips to enable use with smaller

screws and bits.

7.

Pozidriv Screwdriver;

A

better version of Philips Screwdrivers, Pozidriv screwdrivers are designed to

reduce cam-out whenever a screwdriver slips out of the screw head on the

application of more torque.

8.

Hex Screwdriver;

As

the name hints, they, are hexagon screwdrivers used to work with hex screws.

Allen keys or wrenches are representative examples of Hex Screwdrivers.

9.

Square Screwdriver;

To

reduce the cam-out issue of the slotted screws and speed up the fastening

procedures, the square-headed screwdriver that fits screws with a square-shaped

recess was developed.

10.

Electric Screwdrivers and Impact Drivers;

Electric

Screwdrivers are compact powered tools required for various tasks like

assembling furniture or screwing into softwood or other similar material.

Whenever, Impact drivers, are essentially more heavy-duty screwdriver kind that

is used for jobs requiring sudden force to drive into or removed from harder,

denser materials.

11.

Precision Screwdrivers;

Precision

screwdrivers are suitably used for very few devices whenever extremely small screws

are used. Representative examples are mobile phones, watches, etc.

12.

Magnetic Screwdrivers;

Magnetic

Screwdrivers have an inherent magnetic force that allows the screws to be

attached at the tip. These are found in major applications in the electronics

industry where screws are small and have a high potential to be dropped simply.

13.

Ratchet Screwdrivers;

With

a built-in mechanism, these allow the application of force only in one

direction while allowing free movement in the alternative direction, Ratcheting

Screwdrivers work similarly to ratchet spanners.